|

|---|

| IG Home | Newsletters | Group Meetings | Administration | Industrial Applications | Hints & Tips | Group Information | Site Map |

|

|---|

Reports on Industrial Group Meetings 2002

BCA Spring Meeting26th March 2002, NottinghamAn Introduction to Amorphous Materials26 April, 2002 Industrial crystallographers often develop something of a blind spot for am orphous materials, even when they are regularly present in the materials routinely handled. We can try to justify a lack of interest by saying that amorphous phases are not crystalline and therefore not the responsibility of the crystallographer. The fact is, of course, that X-ray and neutron scattering can give much useful information about non-crystalline materials but the techniques of data collection and interpretation take us beyond the familiar world of high order. The session was chaired by < b>Dave Taylor (ICDD) and was, of necessity, a very brief introduction. John Parker (Sheffield) gave helpful summary of “Measurement, Interpretation and Case Studies”, relating much of the tutorial to his interests in glassy materials. The areas covered included: the principles underlying scattering by randomly and non-randomly spaced atoms; problems arising from inelastic scattering and other corrections to experimental data; calculation of the radial distribution func tion and pair correlation function; termination and convergence errors; the need to use shorter wavelengths than Cu and the benefits of neutrons; modelling and network models for glass. An important reason for the decline in laboratory X-ray scattering studies of amorphous materials lies in the need for short wavelengths to access nearest neighbour information. It seems that the most practical options for reliable results (including the alternative approach of EXAFS) mean starting work at a neutron or synchrotron source. Geoff Mitchell (Reading) addressed another area with its own set of problems, “Quantification of Crystalline and Amorphous Fractions”. Much of the talk was framed around examples from the world of semi-crystalline polymers, but the principles were applicable elsewhere. In principle, crystallinity determination should be simply related to the scattering power of the crystalline and amorphous phases. However, even the definition of crystallinity is not simple for polymers and really comes down to the distinction between broad and sharp peaks. This was shown to be relatively easy for some materials such as linear polyethylene at low Q, but increasingly difficult at higher Q due to huge numbers of closely-spaced reflections. There are once again practical problems from necessary corrections, including those for inelastic and parasitic scattering and those for geometry. Issues around peak fitting are crucial and a range of techniques has been used, s ome based on theory that is difficult to put into practice, others on a more pragmatic basis. Establishing the shape of the amorphous component is particularly difficult. Variable temperature measurements and quenching from the melt have been used, but it is important to realise that the amorphous scattering curve can change significantly over a relatively narrow temperature range. Overall, this was a very helpful introduction for many to an area with hidden pitfalls and a useful update for those da bbling in the field over the years. Amorphous materials continue to grow in technological importance (e.g. pharmaceuticals, polymers, electronics, catalysts). Ignoring them because they are “not crystalline” does seem like burying our heads in the quartz. I will not be surprised if this topic appears again soon. Steve Norval Workshop - Powder Diffraction Surgery“Powder diffraction” mea ns different things to different people. This session was a follow-up from the Rietveld refinement workshop and that set the starting point for the discussion. Jeremy Cockcroft was in the chair and his first task, with a little coaxing, was to assemble a ‘panel’ to field the questions. John Evans, Robin Shirley, Lachlan Cranswick and Bill David eventually succumbed and took their places at the front. The discussion started with the optimum experimental conditions fo r ‘H’ positions by neutron diffraction with deuteration. Bill David advocated medium resolution and huge count rates, but it was claimed that the job could be done better by single crystal X-ray diffraction. The optimum solution could depend on whether the atomic positions or electron density maps were sought. The capabilities of national powder diffraction facilities and access to them were obviously close to the hearts of many academic practitioners. The need for both powder and single crystal facilities at Diamond was keenly felt. The ISIS GEM facility was producing “immense” data rates, but what do you do with a thousand patterns a day? Meanwhile, about one case in three was getting beam time at most facilities via peer review. Variable count-rate data collection has long been advocated for Rietveld studies. This is no problem where users write or influence the software, but it would require fundamental modifications to the data formats used by commer cial laboratory systems. The best that could be achieved by those collecting data for Rietveld refinement on such systems was to combine multiple scans over different ranges or boost high angle count rates with programmable slits. It was suggested that the more sophisticated data collection strategies could also help more traditional XRPD applications, such as phase identification. This might just be the route to galvanising manufacturers into action. However, there could be a mountain of software r ewrites, particularly to take account of errors with variable count rates. One thing leads to another, and the lack of publicly available software for merging data sets was bemoaned. It was pointed out that this was the kind of routine that many users would write in a few lines of code. Sadly, it seems that few scientists are now taught programming, so spreadsheets might be more realistic for many. A straw poll showed that Rietveld refinement was being used in industry, sometimes just for the simpler tasks of lattice parameter refinement or phase quantification. In these cases there was no need for the full Rietveld procedures and it was important to choose the parameters for refinement carefully. This led to discussions of the statistical problems associated with background removal and the merits of Pawley and Debye fitting procedures. The applicability of Rietveld to thin films was raised, but there seem to be problems with line shapes. The session ended with a few ever green topics. The Powder Diffraction File is becoming more sophisticated in its database guise and expanding enormously with incorporation of patterns from the inorganic and Cambridge databases. Rather than publish large numbers of full powder patterns, ICDD was incorporating the ability to simulate patterns for different experimental configurations. Optimising diffractometer slits for individual experiments is obviously the right thing to do, unless you work in a laboratory with lots of hands-on us ers and the chaos that might ensue. A small side step from this topic led to the tribulations of variable slits, particularly when they stick in one position. We can all understand the embarrassment of having such difficulties identified after the data has left the lab! This was a wide ranging session that took a little time to get going but eventually got many of the audience involved, covering a range of relevant topics and producing interesting answers. There is clearly an important place for regular open discussions of this type, but the huge range of interests amongst powder diffractionists inevitably results in fewer topics that grab everyone’s attention. Steve Norval Workshop - Introduction to Thin FilmsThis workshop is one of a series of specialist tutorials, run by the Industrial Group, to introduce new users to different X-ray techniques. Glancing Incidence X-Ray Analysis (GIXA) is used to dete rmine the thickness, density and interface roughness and of one or more layers on samples, which are optically flat. Typical examples are anti-reflective coatings applied to glass and also structures used in the electronics industry, i.e. multi-layers on magnetic disks. When a thin layer, (or layers) are irradiated by an X-ray beam which is incident at a low angle (the scan range is typically, 0 to 3° 2q ) an interference pattern is produced . The X-rays are reflected from the interfaces, between the various layers and also the interface between the layers and the substrate. The interference pattern is a function of the thickness, roughness and density of the layers. This information can be extracted from the pattern by fitting a simulated profile based on estimated, starting values. The method is applicable to layers, which are either crystalline or amorphous. Paul Fewster of Philips Analytical Research started the sessi on off by describing the physics behind the simulation. He described how the properties of thickness, roughness and density influence the shape of the pattern. His talk was very well illustrated with some inventive PowerPoint graphics showing the propagation of the wave front through the layers. Paul expanded his argument to include the determination of in- plane crystallite size and lateral correlation. Christoph Schug, of IBM Materials Laboratory, Mainz, Germany described the practic al considerations for GIXA measurements. Firstly, Christoph described the attributes of the ideal sample, both the substrate and the layers: A flat, smooth substrate with an RMS roughness of <10Å which has a sufficient difference in refractive index from the layer(s). For example, use a Ge wafer when studying silicon based layers, as their refractive indices are sufficiently different. The various experimental configurations were then compared and contrasted. Christoph described his favorit e,

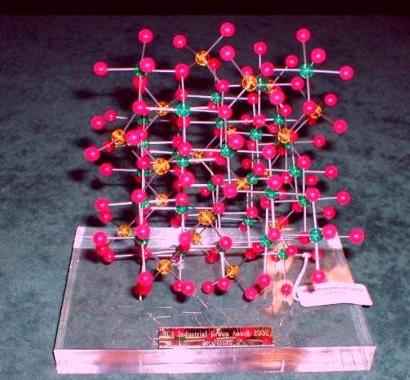

Next the care needed with sample alignment was emphasized and data collection strategies needed to ensure a good fit to the simulated profile. Chr istoph then gave tips to ensure an accurate fit between the measured and simulated data. The talk was illustrated with examples, from a simple NiO layer sputtered on a silicon substrate, to complex examples of the layers on magnetic media. Sadly, we didn't really have enough time to do justice to such an extensive and useful technique, which is quite removed from the more common, powder diffraction methods. However, both speakers made an excellent job, providing a stimulating introduction to a fascinating subject. Judith Shackleton. Autumn Meeting 2002 ReportPlus ca change - or an exile's return. Despite having been a member of the economically-inactive-but-less-than-senior-citizen-age army for the best part of ten years, an Autumn Meeting in Manchester, my home town, was an unmissable opportunity! The Old Dining Room of Hulme Hall, where we were watched ove r by the portraits of distinguished clerical fellows, proved a most suitable venue for an informal but informative presentation of eight papers on Sample Preparation Techniques. I had wondered how much would have changed since I was actively involved in xrd but I found that, although progress has led to further improvements in the hardware, many of the problems discussed were familiar and many of the usual suspects were present at the gathering! We heard of the techniques developed in respon se to sample preparation problems with materials gathered from tidal flats (Martin Gill, Museum of Natural History), from surfactants (Richard Morris, Huntsman Surface Sciences), from aero-engines (Colin Small, Rolls Royce) and from pharmaceutical materials (Chris Frampton, University of Southampton). In addition, the selection and preparation of samples for residual stress and texture measurements (Phil Holdway, QinetiQ) and the practical problems in contract analytical work (Ros Shwartz, London &a mp; Scandinavian Metallurgical) were reviewed. In a paper on lattice parameters and sample displacement, we were reminded of the need to consider possible sources of error arising from the nature of the sample (Mary Vickers, University of Cambridge). A novel idea was the use of a torque wrench to ensure consistent compression of samples needing a binder - that seemed to be a good one! Other papers reminded of the need for an understanding of what we are doing, why we do it the way we do and getting clear what we think we need to find out. In fact, not a lot had changed: all the old things about consistent care, consistent technique, consistent alignment checks remain as true as ever. Industrial Group AwardDuring the Meeting, the latest in the series of Industrial Group Awards was given to Jo Jutson to mark her service to the BCA and her helpful involvement in the wider scientific community. Chris Frampton gave a short address, reviewing Jo's scientific career and contributions. (He omitted to note that this has included scientific presentations to her WI Branch: I wonder if this is unique among recipients of the Award?) Chris invited Jo to give her paper "From Spinel Analysis to Micro X-ray Diffraction - a Personal View of Applications and Advances" which she did with her characteristic modesty and clarity. Jo is pictured receiving the award from Prof Chris Frampton and alongside the Beevers model of a spinel.   Abstracts of all papers are in the IG section of the BCA website, through which the various speakers may be contacted. Congratulations are due to local organiser Judith Shackleton (Manchester Materials Science Centre) and thanks to th e Group Committee for a stimulating, smoothly run Meeting. Eric Kelly. A UK supplier of Single Crystal Silicon for use as zero background substrates for PXRD samples was mentioned in discussion. Contact details are: Crystal Scientific Limited Lee Moor Business Park Rennington Alnwick Northumberland Tel: ++44 1665 572140 Fax: ++44 1665 572141 e-mail: [email protected] Techn ical Contact Dr Simon Cockerton |

|