|

|---|

Industrial Applications of CrystallographyThe Metals and Alloys IndustryAircraft ManufactureResidual Stress Measurement Around Cold-Expanded Holes in High Strength Al Alloys

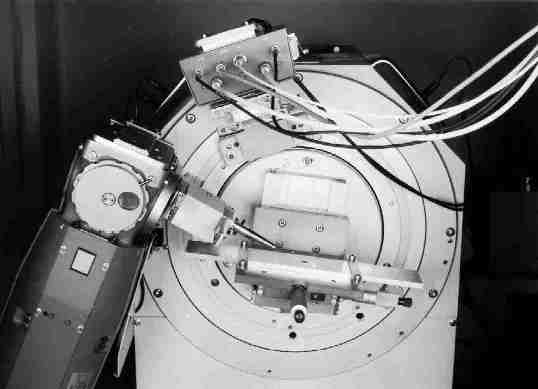

ExampleExperimental set-up showing a Posit ion Sensitive Detector being used to reduce data collection time. A fine collimated beam is used to enable the residual stress field to be mapped around the cold-expanded hole

Plot showing hoop stress after cold-expansion as a function of pre-crack length in Al 7050 alloy RS2 (0.5mm) RS3 (1mm) RS4 (3mm)

|

|

Industrial Group of the BCA

Industrial Group of the BCA